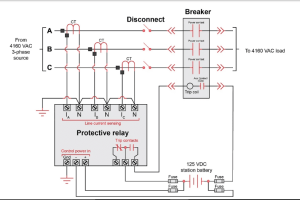

Protective relaying systems serve as the backbone of electrical safety in substations and power systems. These intelligent devices continuously monitor electrical parameters and automatically disconnect faulty equipment to prevent damage and ensure personnel safety. Modern protective relaying combines advanced technology with proven reliability to create a comprehensive safety network that responds instantly to electrical faults, forming the critical foundation of power system protection.

Essential Settings and Configuration Parameters

Proper relay settings form the foundation of effective protective relaying implementation. Each relay must be configured with precise current, voltage, and time parameters that match the specific equipment and system requirements. The pickup settings determine when the protective relaying system will activate, while time delay settings ensure coordinated operation with other protective devices. These settings require careful calculation based on load characteristics, fault levels, and system impedance values to achieve optimal protection without unnecessary interruptions.

Coordination Strategies for Maximum Protection

Effective protective relaying coordination ensures that only the closest protective device to a fault operates, minimizing system disruption. This coordination involves setting time delays and pickup values so that downstream relays operate before upstream devices. Primary protection provides the fastest response to faults, while backup protection offers a safety net if primary systems fail. Proper protective relaying coordination prevents cascading failures and maintains power supply to healthy portions of the electrical system.

Warning Systems and Monitoring Technologies

Advanced warning signals and condition monitoring systems provide early detection of potential problems before they escalate into major faults. These systems continuously track parameters such as temperature, vibration, gas levels, and electrical characteristics. Modern substations integrate smart monitoring technologies that can predict equipment failures and alert operators to developing issues. Real-time data collection enables proactive maintenance decisions and helps prevent unexpected outages.

Maintenance and Inspection Best Practices

Regular inspections and systematic maintenance programs ensure protective relaying systems remain reliable and accurate over time. Testing procedures verify that protective relaying components respond correctly to simulated fault conditions, while calibration ensures measurement accuracy. Preventive maintenance includes checking connections, cleaning contacts, and updating software as needed. Documentation of all maintenance activities helps track system performance and identify trends that might indicate developing problems. Professional maintenance teams should follow manufacturer guidelines and industry standards to maintain optimal protective relaying performance and extend equipment lifespan.

1 Comment

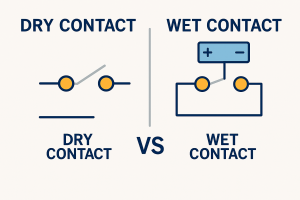

[…] on the condition of the device controlling it. In substations, dry contacts are commonly used in protection relays to send a signal to another device — such as a trip coil or an alarm unit — without passing […]