Hidden Dangers in Power Substations Your Team Must Know

Have you ever wondered what happens when electricity goes wild in a power station? Fault Currents are like electrical tsunamis that can destroy equipment and endanger lives in just milliseconds. These dangerous surges can reach over 100,000 amperes – that’s enough electricity to power thousands of homes, all flowing where it shouldn’t be

What Are Fault Currents?

Imagine water rushing through pipes in your house. Now picture what would happen if one of those pipes suddenly burst – water would spray everywhere with incredible force. Fault Currents are similar, but with electricity instead of water.

A fault current happens when electricity suddenly finds a new, unintended path to flow through. Instead of moving smoothly through its designed route, it surges through equipment, wires, or even the ground with devastating force. This electrical “burst pipe” can happen in milliseconds and cause catastrophic damage.

The Three Main Types of Fault Currents

Ground Fault Currents (The Most Common)

These happen when accidentally touches the ground or the metal casing of equipment. About 70-80% of all electrical problems in power systems are ground faults.

Think of it like this: If you’ve ever seen a downed power line sparking on the ground, that’s a ground fault in action. The electricity is flowing into the earth instead of staying in its proper path.

Different types of grounding affect how dangerous these currents are:

- Ungrounded systems: Very little current flows, but the danger can be hidden

- High-impedance grounding: Limits the current to 25 amperes or less (safer)

- Low-impedance grounding: Can produce very high currents that need immediate isolation

Good news: About 80% of ground faults on overhead power lines fix themselves automatically when the cause (like a tree branch) falls away.

Line-to-Line Fault Currents (Medium Danger)

These occur when two electrical wires that shouldn’t touch each other make contact. They make up about 15-20% of all electrical system problems.

Real-world example: Think of two extension cords with damaged insulation touching each other. In a power system, this creates a fault current that’s about 87% as strong as the worst-case scenario.

Why they happen:

- Insulation breaks down over time

- Equipment fails

- Poor maintenance

- Weather damage

Three-Phase Fault Currents (The Most Dangerous)

These are rare but extremely dangerous. All three main electrical wires in the system get connected when they shouldn’t be. While they only happen 2-5% of the time, they create the most powerful and destructive currents.

Two types exist:

- Line-to-line-to-line: All three wires short together (no ground involved)

- Line-to-line-to-line-to-ground: All wires fault to ground at the same time

Why they’re so dangerous: These faults typically produce the highest fault currents, which is why engineers use them as the worst-case scenario when designing safety equipment.

What Causes These Dangerous Fault Currents?

Equipment Getting Old and Worn Out

Just like an old car that starts breaking down, electrical equipment deteriorates over time:

Insulation Problems:

- The protective covering around wires cracks from repeated heating and cooling

- Dust, moisture, and chemicals create paths for electricity to escape

- Metal parts corrode and lose their strength

The Domino Effect: When one connection fails, it overheats, which makes bolts stretch and become loose, creating even more heat and more problems.

Weather-Related Causes

Lightning Strikes:

- Can create electrical arcs over 200,000 amperes

- Lightning within 2 miles of a power station is particularly dangerous

- Causes up to 20% of all power outages in the U.S. annually

- Results in over $1 billion in property damage each year

Switching Surges:

- Happen more often than lightning strikes

- Occur when electrical equipment is turned on or off

- Create enormous energy bursts that last longer than lightning

- Can be affected by the exact moment the switch is operated

Mechanical Stress and Aging

Through-Fault Currents (TFC): These are currents that flow through equipment (like transformers) when faults happen elsewhere in the system. While one incident rarely causes immediate failure, repeated exposure weakens the equipment over time, like repeatedly bending a paperclip until it breaks.

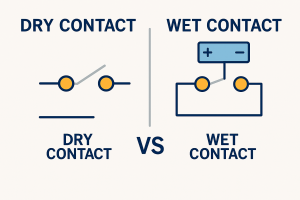

Poor Installation and Grounding

When electrical systems aren’t properly connected to the earth (grounded), several dangerous things can happen:

- Equipment casings can become electrically charged

- Fault currents can’t be safely directed into the ground

- Voltage spikes can damage equipment

- Safety systems may not work properly

The Hidden Dangers of Fault Currents

Arc Flash: Indoor Lightning, When fault currents create electrical arcs, they produce what’s called an “arc flash” – essentially artificial lightning that can:

- Reach temperatures of 35,000°F (four times hotter than the sun’s surface)

- Create explosive sounds that can damage hearing

- Produce supersonic shock waves

- Generate superheated metal fragments that fly like shrapnel

- Ignite clothing and cause severe burns

Scary fact: In 2019 alone, 39 people died in electrical substations, many from arc flash incidents.

Equipment Destruction

Fault currents are like floods of electricity that destroy everything in their path:

- Transformers: The insulation becomes brittle (like overcooked food) and can catch fire

- Circuit breakers: May not be fast enough to stop the current

- Cables and wires: Can melt or burn from the excessive current

The Domino Effect (Cascading Failures)

Sometimes one fault current causes another problem, which causes another, creating a chain reaction:

- In 2006, a European power failure caused 33 major power lines to fail in just 1 minute and 20 seconds

- 30 of those lines failed in the first 19 seconds

This left millions of people without electricity

How Engineers Fight Fault Currents

Detection and Analysis Tools

Engineers use sophisticated computer programs to:

- Simulate what would happen if different types of fault currents occurred

- Calculate how much current would flow

- Determine which equipment might be damaged

- Design better protection systems

Popular software tools

ETAP and SKM help engineers analyze fault currents and design safer systems.

Protection Equipment

Current Limiting Reactors:

- Like speed bumps for electricity

- Slow down fault currents to safer levels

- Made of special coils that resist the flow of electricity during faults

Current-Limiting Fuses:

- Designed to burn out safely when too much current flows

- Work incredibly fast (less than 0.00833 seconds)

- Protect equipment from catastrophic failure

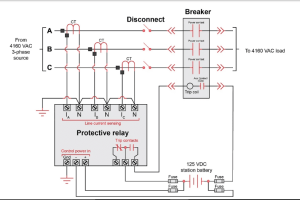

Circuit Breakers and Protective Relays:

- Act like super-fast electrical switches

- Monitor electrical conditions constantly

- Turn off power when they detect dangerous fault currents

Smart Protection Strategies

Selective Coordination:

Think of this like having multiple fire doors in a building. When there’s a fire (fault current) in one room, only that room’s door closes, not every door in the building. This keeps the rest of the system running while isolating the problem.

Protection Zones: Power systems are divided into different safety zones, like having different security levels in a building. Each zone has its own protection, so a problem in one area doesn’t affect the others.

Safety Measures That Save Lives

Personal Protective Equipment (PPE)

Workers wear special gear designed to protect them from arc flash:

- Flame-resistant clothing that won’t catch fire

- Arc-rated face shields and helmets

- Insulated gloves and boots

- Safety glasses for eye protection

Important: Most arc flash injuries happen when regular clothing catches fire, not from the electrical arc itself.

Regular Testing and Maintenance

Just like getting regular check-ups at the doctor, electrical equipment needs constant monitoring:

- Circuit breaker testing every two years

- Predictive maintenance that monitors equipment in real-time

- Regular inspections to catch problems early

This approach saves 8-12% in costs compared to fixing things after they break.

Why Fault Currents Matter to Everyone

Power Outages

When fault currents damage equipment, entire communities can lose power, affecting:

- Hospitals and emergency services

- Traffic lights and transportation

- Businesses and schools

- Home heating, cooling, and appliances

Economic Impact

Fault currents and the outages they cause cost billions of dollars every year through:

- Lost business productivity

- Spoiled food and medicine

- Damaged electronic equipment

- Emergency response costs

Safety Risks

Unexpected power outages create dangerous situations:

- People trapped in elevators

- Traffic accidents at dark intersections

- Medical equipment failures

- Increased security risks

What You Can Do

While most fault current protection happens at the utility level, you can help at home:

- Have your electrical system inspected regularly

- Don’t overload circuits or outlets

- Replace old, damaged electrical cords

- Install surge protectors for valuable electronics

- Never attempt electrical repairs unless you’re qualified

- Report electrical problems to your utility company immediately

The Bottom Line

Fault currents are invisible dangers that can cause massive destruction in milliseconds. They’re like electrical tsunamis that can:

- Destroy expensive equipment instantly

- Cause widespread power outages

- Injure or kill workers

- Cost society billions of dollars

But with proper understanding, advanced protection equipment, and regular maintenance, these dangers can be controlled. The next time you flip a light switch and it works perfectly, remember that teams of engineers are working around the clock to keep fault currents from disrupting your life.

Understanding fault currents helps us appreciate the incredible complexity of our electrical system and the importance of treating electricity with respect. After all, the same force that powers our modern world can be devastatingly dangerous when it goes where it shouldn’t.