Power Substation Construction

Civil works & Initial Electrical

Electrical substations are critical components of the power distribution network, serving to transform voltage levels and facilitate the transmission of electricity. The construction process involves several key stages, including site selection, design, civil works, and installation of electrical equipment.

The foundation of successful substation construction begins with proper civil works integration. During the construction of GIS buildings, control rooms, tunnels, and transformer foundations, all electrical requirements must be carefully planned. This includes incorporating sleeves, openings, and earthing points according to approved drawings. Once the building’s raft is complete, teams can begin installing cable trays, earthing systems, and lighting works. This early integration prevents costly modifications later.

GIS Installation and Panel Setup

After completing the building’s grey structure, the focus shifts to Gas Insulated Switchgear (GIS) installation. This phase requires specialized equipment such as fork lifters and overhead cranes, with supervision from manufacturer representatives like ABB, Siemens, or Hyundai. Following GIS erection, Local Control Cubicle (LCC) panels are installed and coupled. The process continues with earthing and cable pulling between LCC and various components including GIS, CT, VT, DC, ES, and CBs. A crucial priority is establishing temporary DC supply for LCC panels while connecting all necessary cables.

Control Room Setup and Cable Management

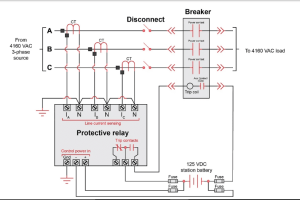

The control room setup begins with proper earthing of all panels using specified copper tape installed in the basement. Cable management is a critical aspect, involving both internal and external AC/DC cable pulling. Precise attention must be paid to cable glanding, dressing, and ferrule marking according to termination schedules and drawings. This phase requires methodical execution of various schemes including TCS, Bus bar, BF, Annunciation, SCADA, SOE, TFR, SAS, PSE, and Communication systems.

Testing and Commissioning

The final phase involves comprehensive testing of all installations. This begins with internal checks of panel wiring, ferrules, and connections, followed by testing of auxiliary relays and MCBs. CT and VT loop tests precede function testing of GIS LCC Panels and Control Protection Panels. For substations with SCADA or SAS systems, specific panel testing is required. In existing substation extensions, point lists and interfacing drawings guide cable termination. The process concludes with open and closed loop testing, requiring coordination between site engineers and the master station for thorough system verification.

Conclusion

In Saudi Arabia, electrical substation construction adheres to stringent SEC (Saudi Electricity Company) standards, incorporating advanced technologies and robust testing protocols while accounting for unique environmental challenges. This ensures reliable power infrastructure across the Kingdom.

3 Comments

substationfaults.com

substationfaults.com

substationfaults.com

substationfaults.com