Contact types in the electrical system

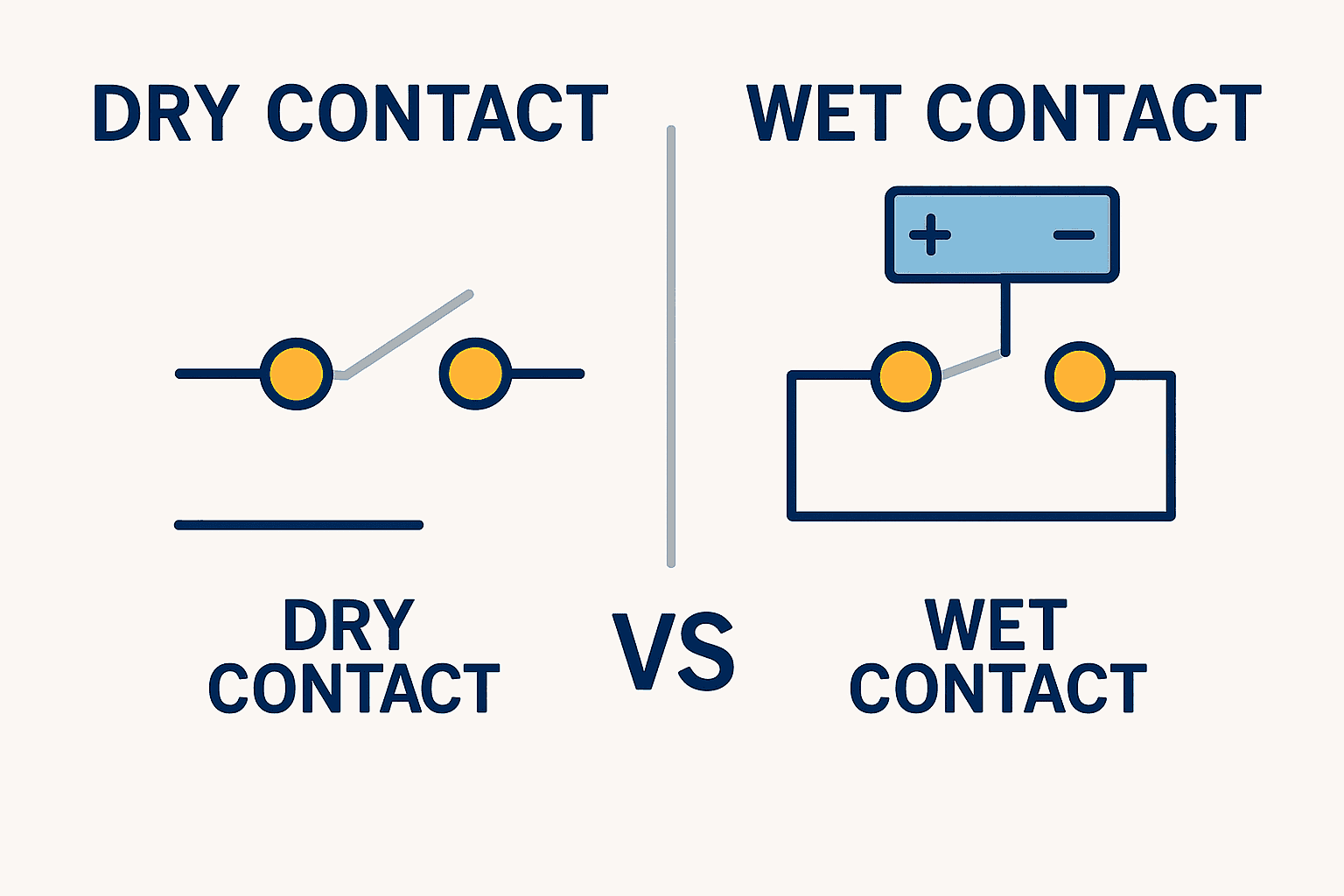

In electrical control systems and substation equipment, contactor relays use two main types of contacts: dry contact vs wet contact. These contacts control how electricity flows through circuits and play essential roles in protection relay systems and electrical circuit troubleshooting. Understanding the difference helps prevent substation faults and ensures safe operation of circuit breakers and control systems.

Dry Contacts in Contactor Relays

Dry contacts in contactor relays have no electrical supply from either side. Think of them as empty pipes – they can open or close the path, but no water (electricity) flows through them until you connect an external source. These contacts work widely in industrial automation systems for safe control applications.

When a contactor coil energizes, the dry contact simply changes its position (opens or closes), but it carries no voltage or current from the contactor itself. The power for the controlled circuit comes from a completely separate external source.

Key Features of Dry Contacts

No voltage present on contact terminals | Complete electrical isolation between coil circuit and contact circuit | External power source required for operation | Safe for electrical circuit troubleshooting

Wet Contacts in Contactor Relays

Wet contacts in contactor relays have an electrical supply available on one side. When the contactor coil gets energized, the normally open contact closes and allows the supply to pass through to the concerned object or load.

Imagine a water tap – when you turn it on (energize the coil), water (electricity) flows from the supply side through the contact to whatever connects on the other side. This “other side” could be a motor, light, heater, fan, or any electrical equipment that needs power to operate. The wet contact acts like a bridge that connects the power supply to your load equipment.

Key Features of Wet Contacts

Supply voltage present on one terminal | Direct power transmission through contact | No external power source needed | Power comes from the same system as the coil

Practical Example: Motor Control System

Dry Contact Example:

A protection relay in a power substation uses dry contacts to signal a motor control panel. When a fault current occurs:

- The protection relay coil energizes

- Dry contact closes (no voltage on the contact itself)

- External 24V DC supply from the control panel flows through the closed contact

- The motor control system receives a signal and stops the motor

- Circuit breaker trips safely

Benefit: The high-voltage protection system stays completely isolated from the low-voltage control system, preventing substation faults.

Wet Contact Example:

A contactor controlling a cooling fan uses wet contacts:

- The temperature sensor signals the contactor coil to energize

- Wet contact closes with a 230V supply already present on one side

- 230V flows directly through the closed contact to the cooling fan

- The fan starts running immediately

- No external power source needed

Benefit: Simple, direct control with fewer wiring connections.

When to Use Each Type

Use Dry Contacts For:

Substation equipment interfacing | Protection relay applications | Electrical circuit troubleshooting access points | Safety-critical systems | Different voltage level systems

Use Wet Contacts For:

Simple motor control | Direct load switching | Same voltage systems | Cost-effective solutions

Safety and Maintenance

Dry contacts offer safer electrical circuit troubleshooting because no live voltage exists on the contact itself. This makes maintenance easier and reduces shock risk.

Wet contacts require more caution as they carry live voltage. Always use proper lockout/tagout procedures and PPE when working on wet contact systems. For detailed safety guidelines regarding Dry contact vs wet contact, please take a look at the OSHA electrical safety standards.

Conclusion

Both dry and wet contacts have important roles in Substation Automation and Protection. Choosing the right contact type and understanding dry and wet contacts in contactor relays remains crucial for electrical professionals. Dry contacts provide safety and isolation but need external power. Wet contacts offer simplicity with direct power flow. Choose based on your system requirements, safety needs, and electrical circuit troubleshooting accessibility.

For substation applications and protection relay systems, dry contacts work better due to their isolation properties and enhanced safety features. You can learn more about the fundamentals of electrical relays for advanced applications.