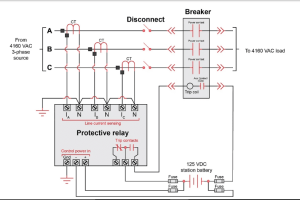

In high-voltage substations, maintaining proper isolation between DC control circuits is crucial for reliable operation. This case study examines how we resolved persistent 110V DC mixing issues in 132kV circuits, highlighting the importance of systematic troubleshooting and attention to detail.

The Initial Problem of DC Mixing Issues

Our maintenance team encountered abnormal behaviour in the substation’s DC system due to DC mixing issues:

- Uneven current distribution between DC rectifiers

- DC-1 and DC-2 systems showing unexpected mixing when tested

- Potential safety and reliability concerns due to improper circuit isolation

Step-by-Step Investigation of DC mixing issues

Phase 1: Circuit Breaker Cubicle Inspection

During our initial investigation, we discovered incorrect shorting links in the 132kV circuit breaker cubicle. These links, connecting terminals X1:600-602 and X1:605-607, should have been removed during commissioning but were overlooked. After removing these links and rewiring the closing and opening circuits, we verified proper circuit breaker operation both locally and remotely.

Phase 2: Wiring Verification of DC mixing problems

Further investigation revealed swapped wiring in the E7Q1 MK panel. Despite correcting this issue, the DC mixing problem persisted, indicating a deeper underlying cause.

Phase 3: Systematic Isolation Testing

We conducted comprehensive isolation tests to pinpoint the source:

- With DC-1 OFF and DC-2 ON: No return voltage detected in DC-1 circuits

- With DC-2 OFF and DC-1 ON: Discovered 60V return on both positive and negative wires in 2Q21 MCB

Phase 4: Component-Level Diagnosis

The breakthrough came when tracing voltages through various components:

- Bus-2 terminal showed no voltage after wire removal

- MCB 210 exhibited unusual behavior with output voltage present despite no input

- Traced the issue to the KC Contactor, where DC-1 and DC-2 circuits were cross-feeding through NC and NO contacts

Root Cause and Solution of DC mixing problems

The investigation revealed that a faulty KC contactor was the primary culprit. The contactor’s deteriorated condition allowed unintended current paths between the DC-1 and DC-2 circuits through its normally closed and normally open contacts. Replacing the contactor completely resolved the long-standing issue.

Key Takeaways

- Always verify commissioning procedures are fully completed

- Use systematic isolation testing when troubleshooting complex electrical issues

- Don’t assume the first problem found is the only issue

- Component-level testing is crucial for resolving persistent problems

Conclusion

This case demonstrates the importance of methodical troubleshooting in high-voltage environments. While initial findings may point to obvious issues like missing commissioning steps, persistent problems often require deeper investigation at the component level.

This technical case study is part of our ongoing series on substation maintenance and troubleshooting. For more information about DC system maintenance in high-voltage substations, visit our technical resources section.